IQTouch incorporates optical bonding technology to interactive flat panel for best user experience. The benefits of optical bonding touch screen are providing a better viewing and more accurate touch experience for users. IQTouch optical bonding displays include HA1100 Pro and HC900 Pro.

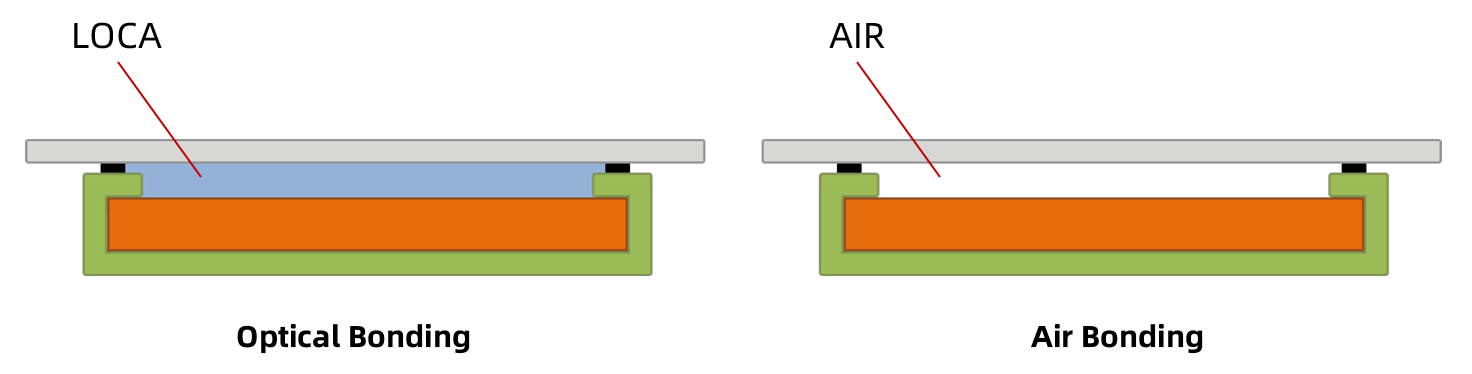

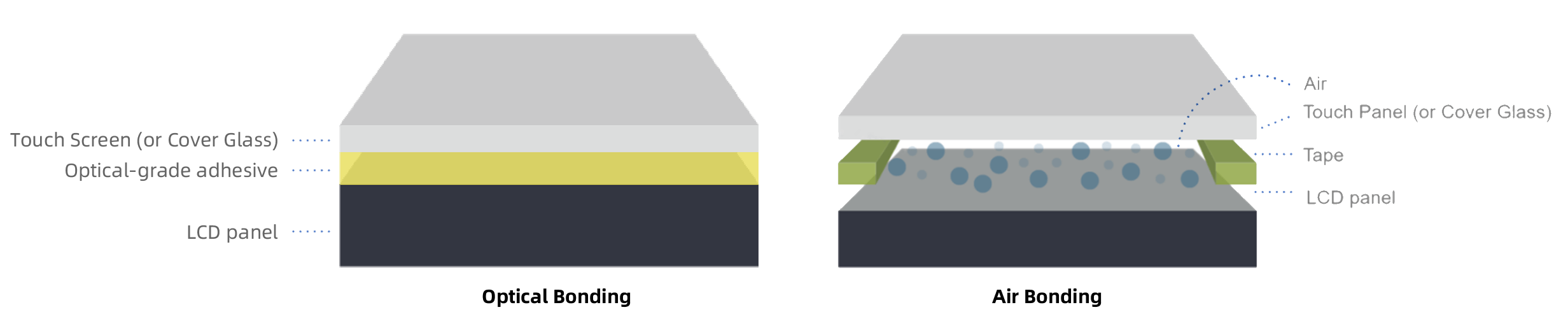

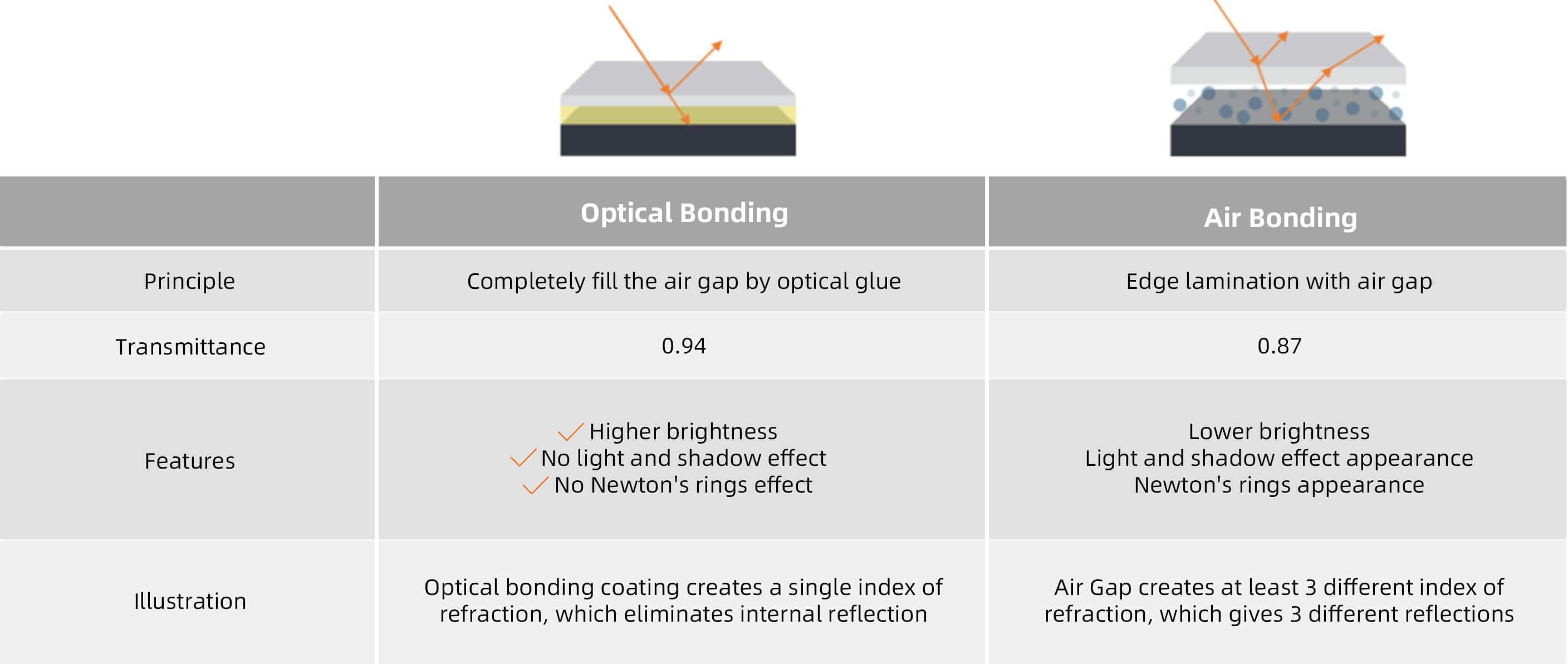

Optical bonding is the use of an optical-grade adhesive to glue a glass to the top surface of a display.It eliminates the air gap and makes sure absolute vacuum between the LCD panel and the touch screen.

Before optical bonding, air bonding is the most commonly used technology in making a touch screen. When bonding the cover glass to the touch sensor, it’s simple to just place the adhesive to the edges of the glass. However it leaves a small air gap between the LCD panel and the screen glass, which causes various problems to the overall performance of the interactive touch screen.

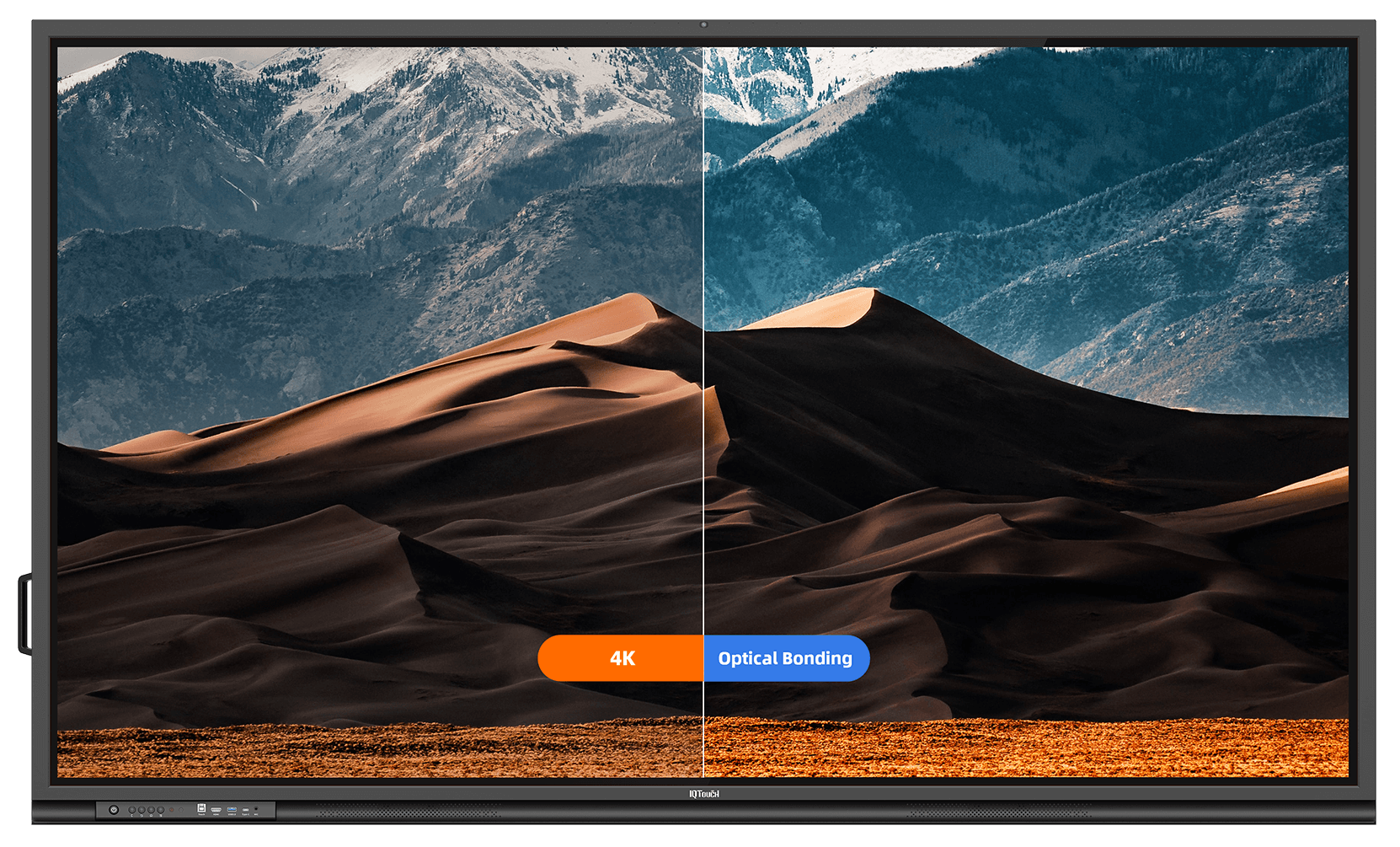

The transmission of light is increased with optical bonding, more light gets through to the surface of the screen, resulting in a clearer display.

Without the air gap, the internal reflection between the cover glass and the LCD panel has been totally eliminated, which allows a wider viewing angle for users. No matter where you are seated, even in the most front side of the room, the display can be seen clearly without reflection.

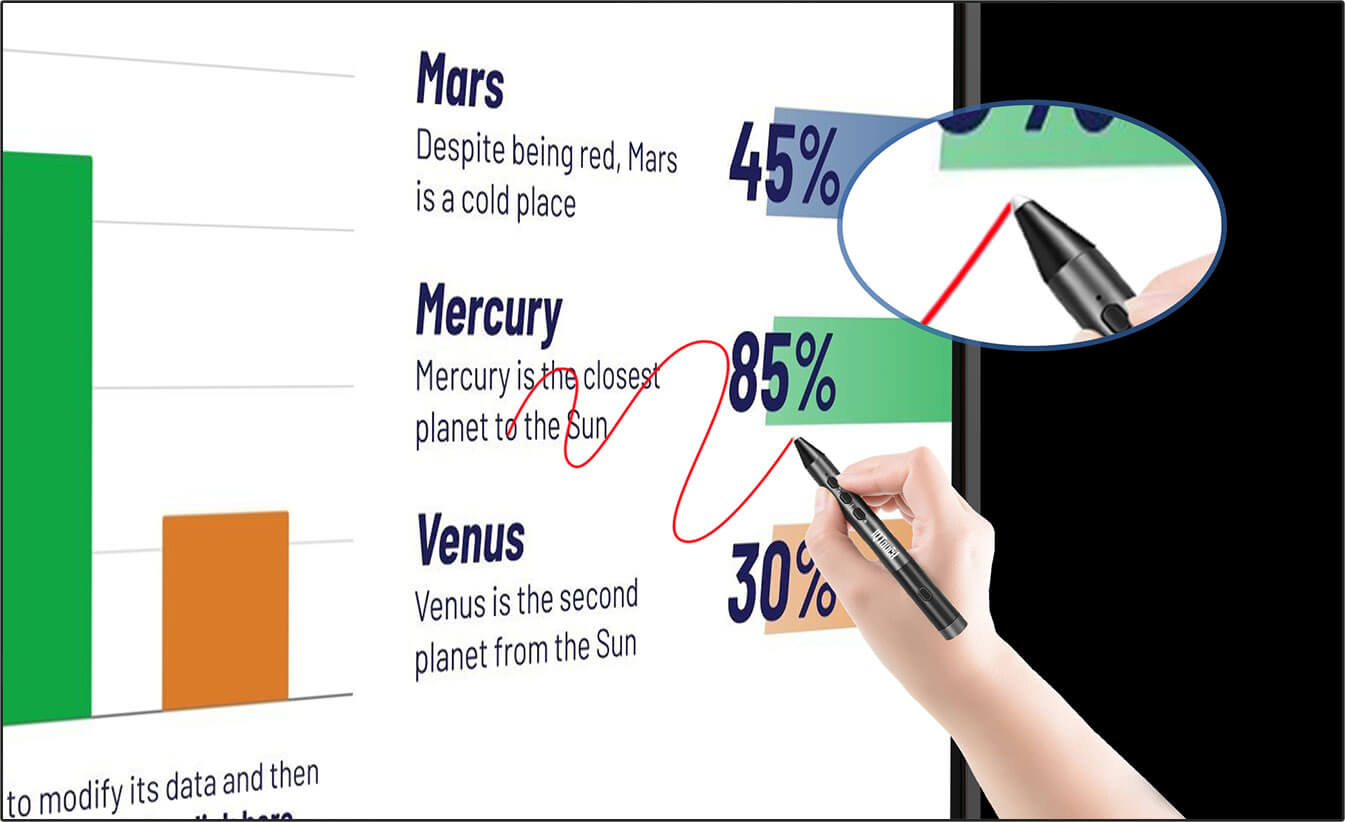

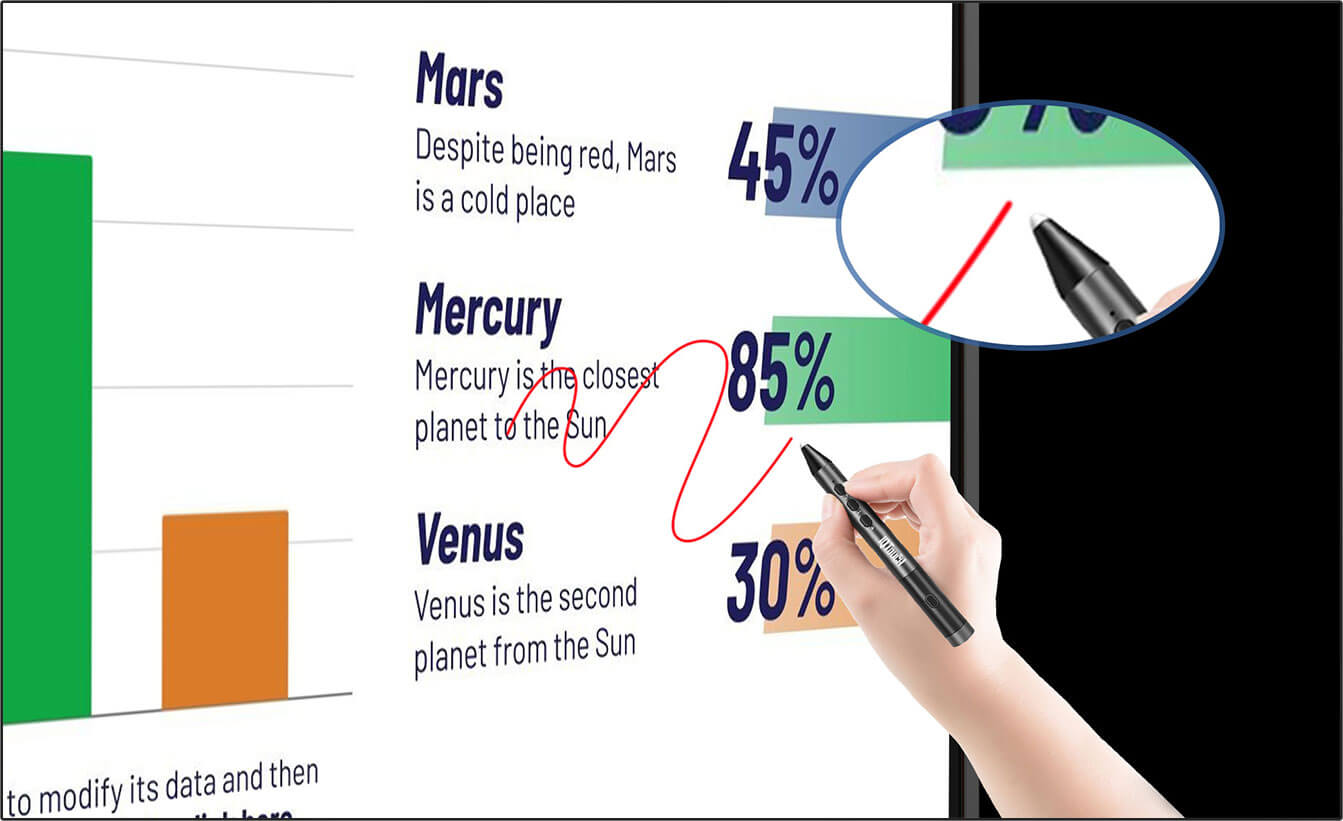

With optical bonding

Without optical bonding

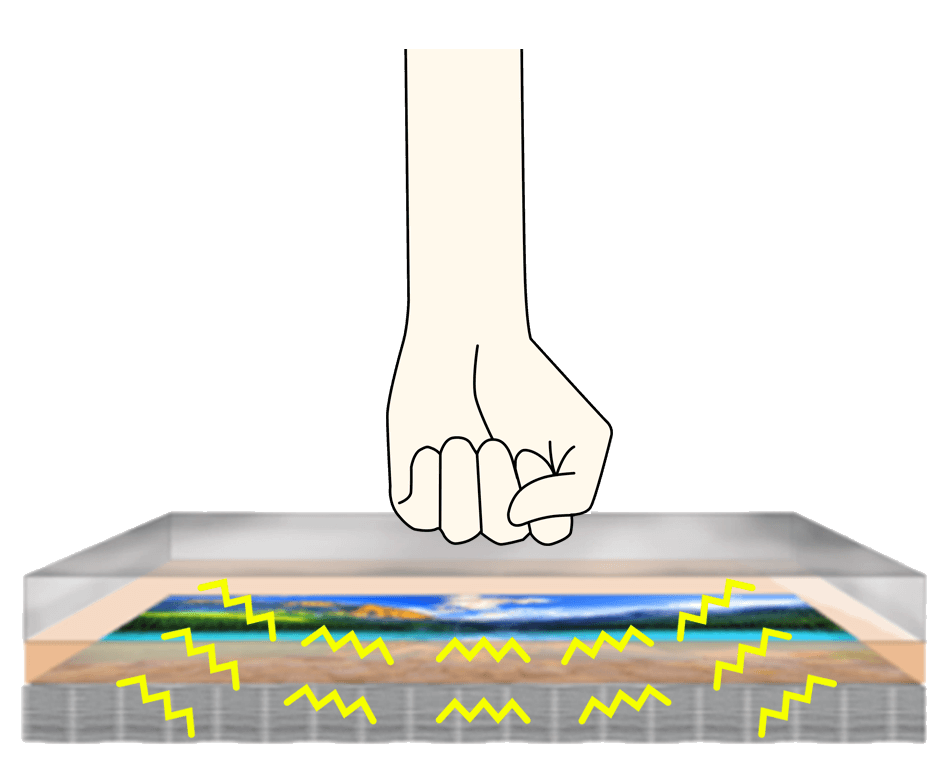

Air bonding creates the refraction angle of light, so that the actual handwriting of a pen on the glass can not follow closely with the pen tip, resulting to a poor user experience. Optically bonded displays lower the refractive index and provide more accurate touch screen response with zero deviation. There's no gap between the LCD panel and the covered glass, which makes the writing experience smoother than ever -- just like the way you did on an ordinary whiteboard.

Optical bonding

Air bonding

With reducing the reflection of light, the screen visibility is higher in bright ambient environments.

With optical bonding

Shows properly

Without optical bonding

Appears light and shadow effect

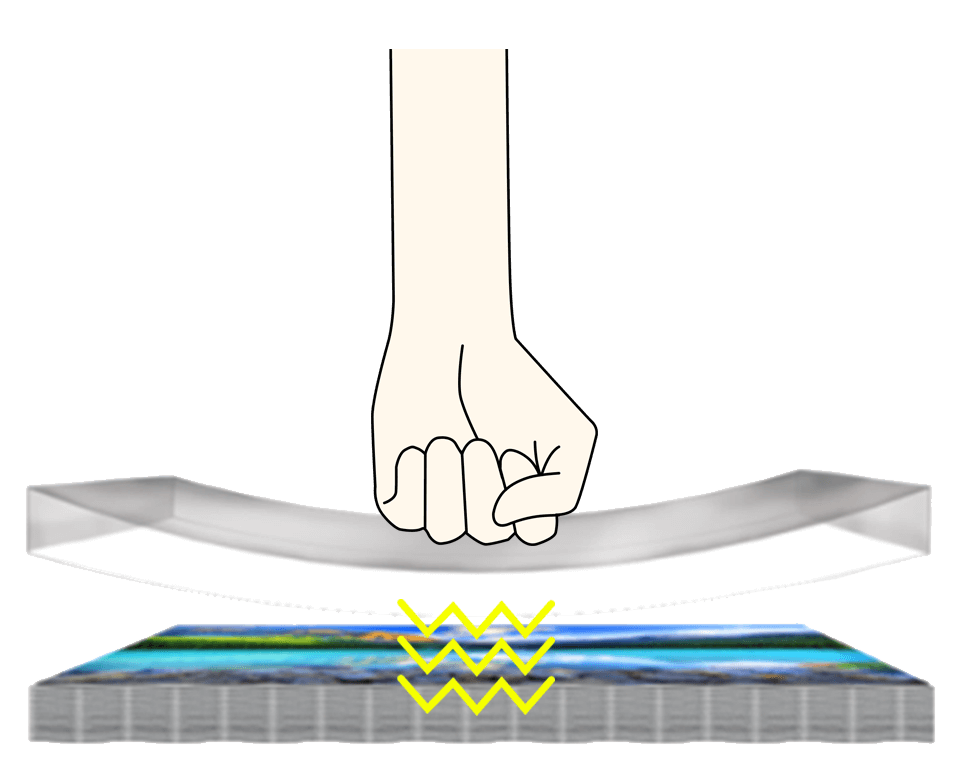

Survivor for rough transportation and violent damage.

With optical bonding

The Optical Bonding layer increases

physical durability to the screen.

Without optical bonding

The air gap between the LCD reduces the

durability and the resistance against shock and

extreme use.

Survivor for rough transportation and violent damage.

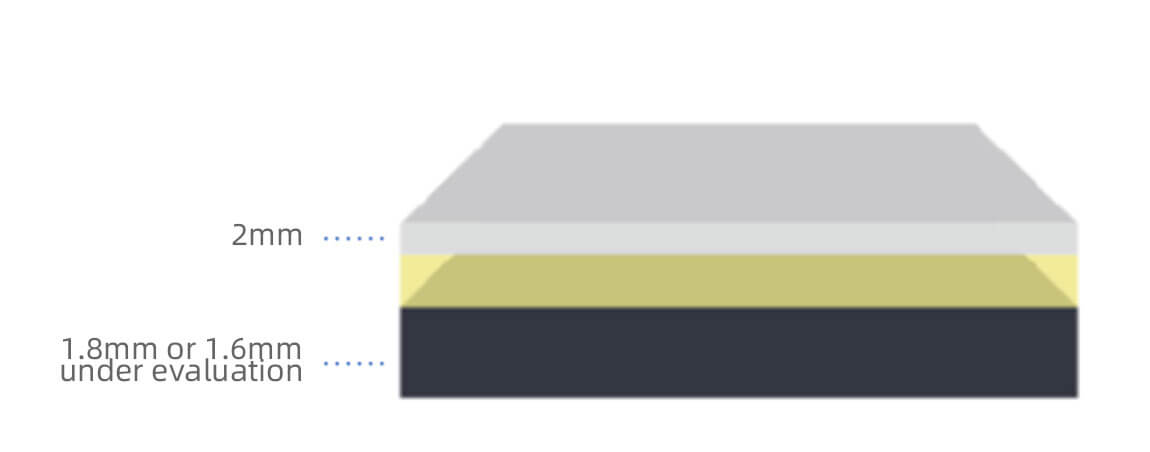

The overall thickness of finished product

is reduced.Make sure a more protective glass.

The overall thickness of finished product

can not be reduced.

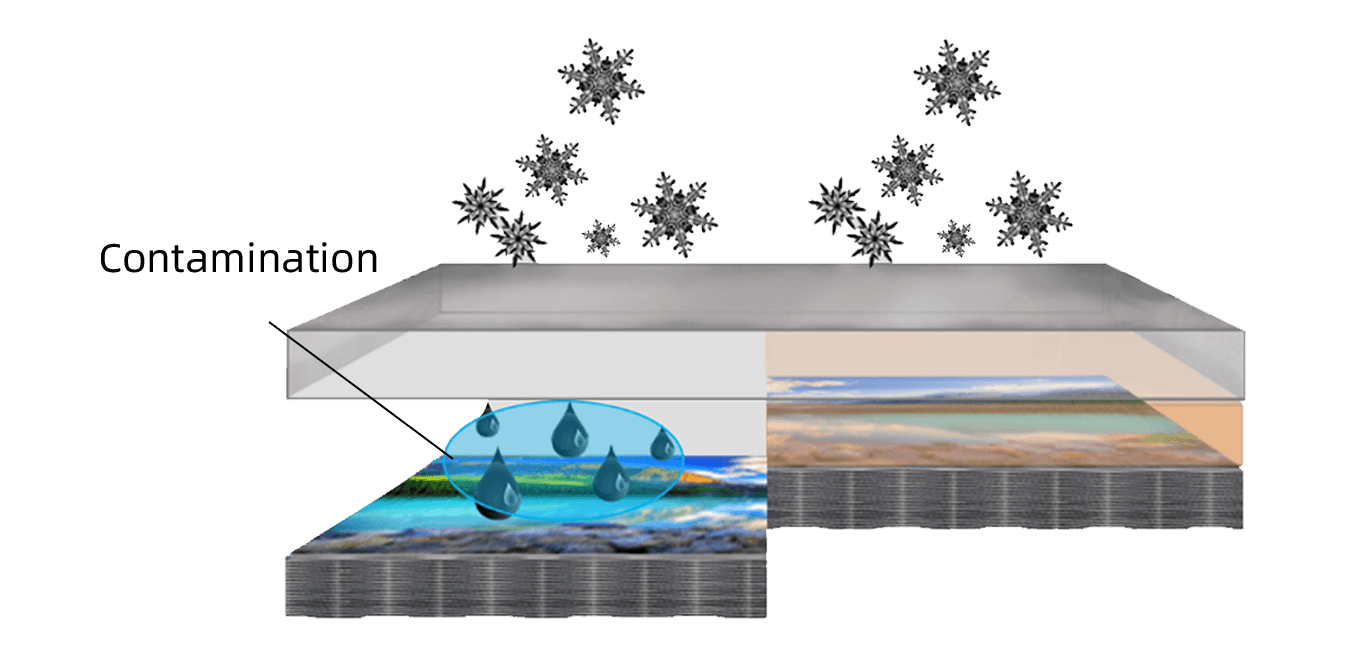

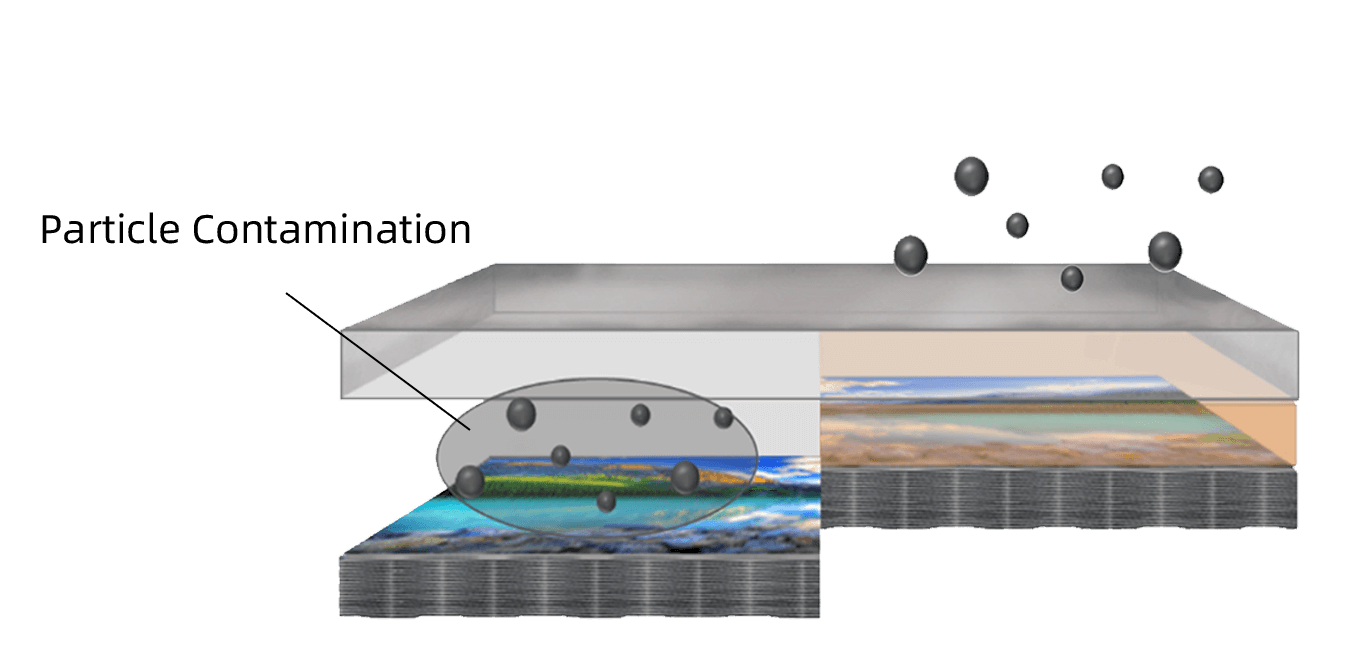

Without optical bonding

When environmental temperature

ranges are wide, condensation

usually causes foggy effect from

moisture that penetrates the air gap.

With optical bonding

Optical Bonding fills the gap

to avoid any condensation.

Without optical bonding

Where air quality is an issue air gap

can expose the screen dust and air.

With optical bonding

Optical Bonding fills the gap

to avoid any contamination.

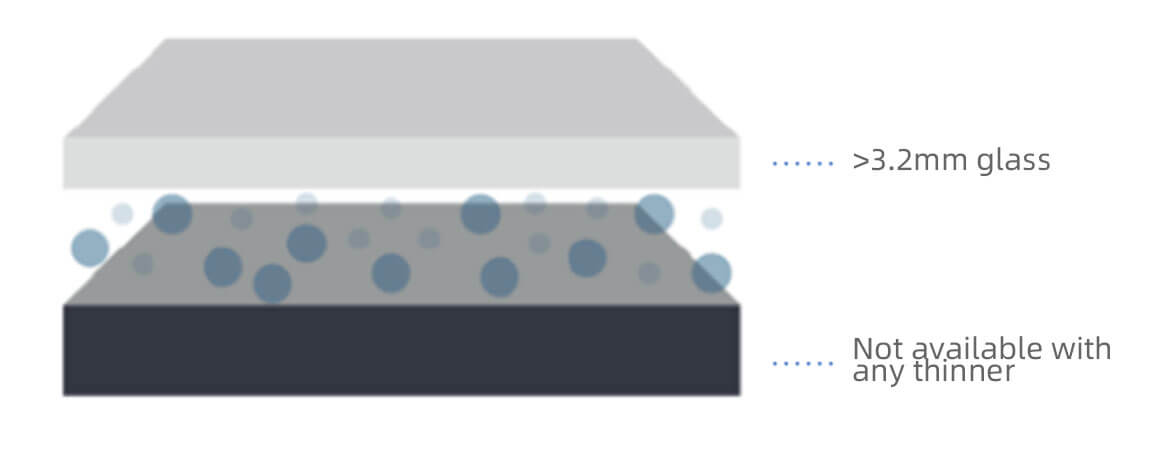

Air bonding always come with air inside. Air mean potential water and particle inside. It causes condensation and contamination occurred.

Air bonding always come with air inside. Air mean potential water and particle inside. It causes condensation and contamination occurred.

Optical bonding makes sure optical glue without any air and particles inside. No condensation & contamination problem.

Optical bonding makes sure optical glue without any air and particles inside. No condensation & contamination problem.

Copyright © 2017.Returnstar Interactive Technology Group Co., Ltd All rights reserved.